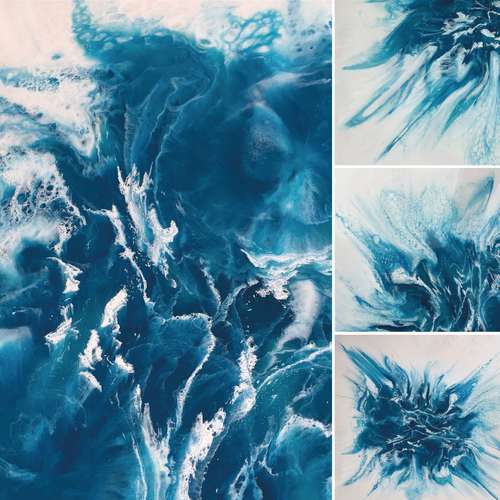

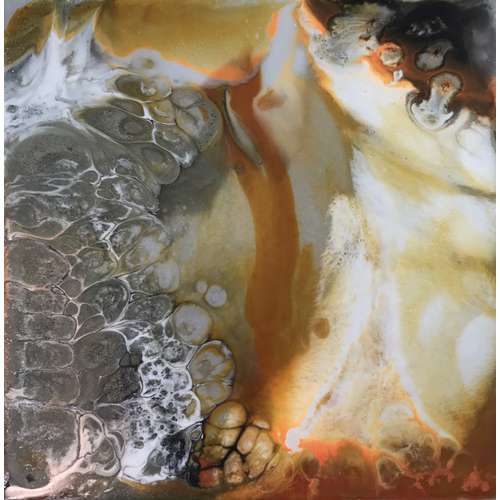

MasterCast 1-2-1 Clear Artwork Resin Kits

MasterCast 1-2-1 Clear Artwork Resin is a two-component polymer material that produces a perfectly transparent, high gloss finish on a range surfaces including canvas, wood, mdf, glass, perspex, concrete and metal.

The clarity of the resin makes it particularly suitable for protecting and decorating works of art including layered collages, table tops, wood artefacts, photos, puzzles, badges and jewellery. The resin can be poured, or applied to the surface with a brush or roller.

MasterCast is certified by the American Society for Testing and Materials (conforms to ASTM D4236). It is developed from the highest quality materials and therefore produces no VOCs or fumes.

No solvents or reactive diluents are used. All ingredients are designed in such a way that no harmful substances escape. In addition, it is non-flammable.

MasterCast is almost odorless and very user-friendly. Mix ratio 1:1 by volume

MasterCast 1-2-1 Clear Artwork Resin cures at ambient temperature, is high build and U.V. stable. It gives the best possible protection against yellowing. MasterCast 1-2-1 Clear Artwork Resin Kits are available in the following sizes:

- 49683 - 400g tester kit

- 49684 - 2kg kit

- 49685 - 4kg kit

- 49686 - 10kg kit

Price per kit.

The most important questions about MasterCast 1-2-1 Artwork Resin:

What are the differences between MasterCast and totalCAST?

They differ mainly in their viscosity and the processing time. TotalCast is slightly more liquid than MasterCast, which has a medium viscosity. The curing time of TotalCast is approx. 3-4 hours, that of MasterCast approx. 6-8 hours. MasterCast offers a longer working time (usage time) . Both can be used for a clear coating. MasterCast is better suited for coloring resin art (fluid painting). totalCAST is ideal for clear coatings or embedding and pouring of liquids.

How do you apply MasterCast 1-2-1?

Depending on your workpiece, you can apply MasterCast in different ways:

by pouring

With the brush

With the foam roller

Apply with a spatula

What is the working time of MasterCast?

At a room temperature of 22 degrees, the drying phase begins after about 25-30 minutes. Various factors can extend the processing time by up to 40 minutes.

How do you properly mix MasterCast?

The mixing ratio of resin and hardener is 1:1 by volume. Always mix by slow stirring for at least 2-3 minutes until the mixture has a uniform texture and consistency.

Mixing creates a chemical reaction. Leave the finished mixture in the mixing vessel for no more than 4-5 minutes. In a small volumetric space, MasterCast quickly becomes exothermic. This can cause heat to develop, which accelerates curing and thus shortens the processing time.

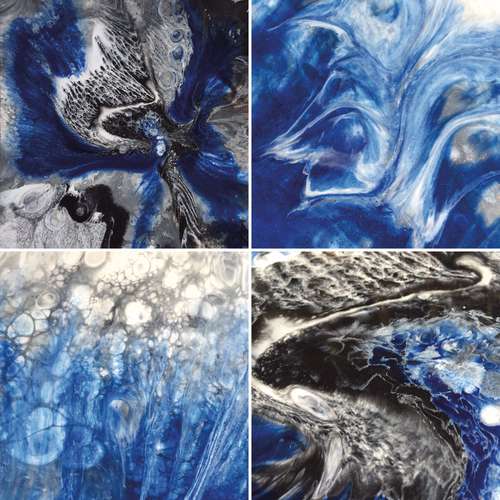

How do you add colors and unique effects to the resin?

The Resi-Tint range of polymer pigments is the ideal way to add color without affecting the resin's curing process and properties. Resi-Tint is highly pigmented and matched to the resins. Due to the very high pigmentation, you only need a small amount (1 ml pigment to 1000 ml resin) to turn the clear resin into brilliant colors.

You can of course add a variety of other pigments to the resin. Great effects, textures and cells can be obtained by adding ResiBlast.

What quantity do you need for which area?

This depends on whether the resin runs over the edges or stays within the area due to a boundary (adhesive tape). Example: If the resin stays within the area, you will need approx. 1.2 liters for an area of 1 m x 1 m. If it runs over the edges, calculate 1.5 liters.

Does yellowing occur when using MasterCast 1-2-1?

MasterCast has the maximum protection against yellowing. It contains a UV stabilizer and also a substance called HALS (hindered amine light stabilizer). HALS interrupts the yellowing process before it can begin.

Is MasterCast 1-2-1 food safe?

Yes! Once the resins have hardened, contact with food is completely safe. Not suitable as a cutting board for preparing meals.

Is MasterCast self-leveling?

On a flat surface, MasterCast will self-level to a thickness of approximately 8mm. Therefore, you should work with a spirit level. Just make sure the surface is straight. You can apply multiple layers. Allow each coat to cure before applying the next.

How heat resistant is MasterCast?

MasterCast has a heat resistance up to 45-50 degrees C.